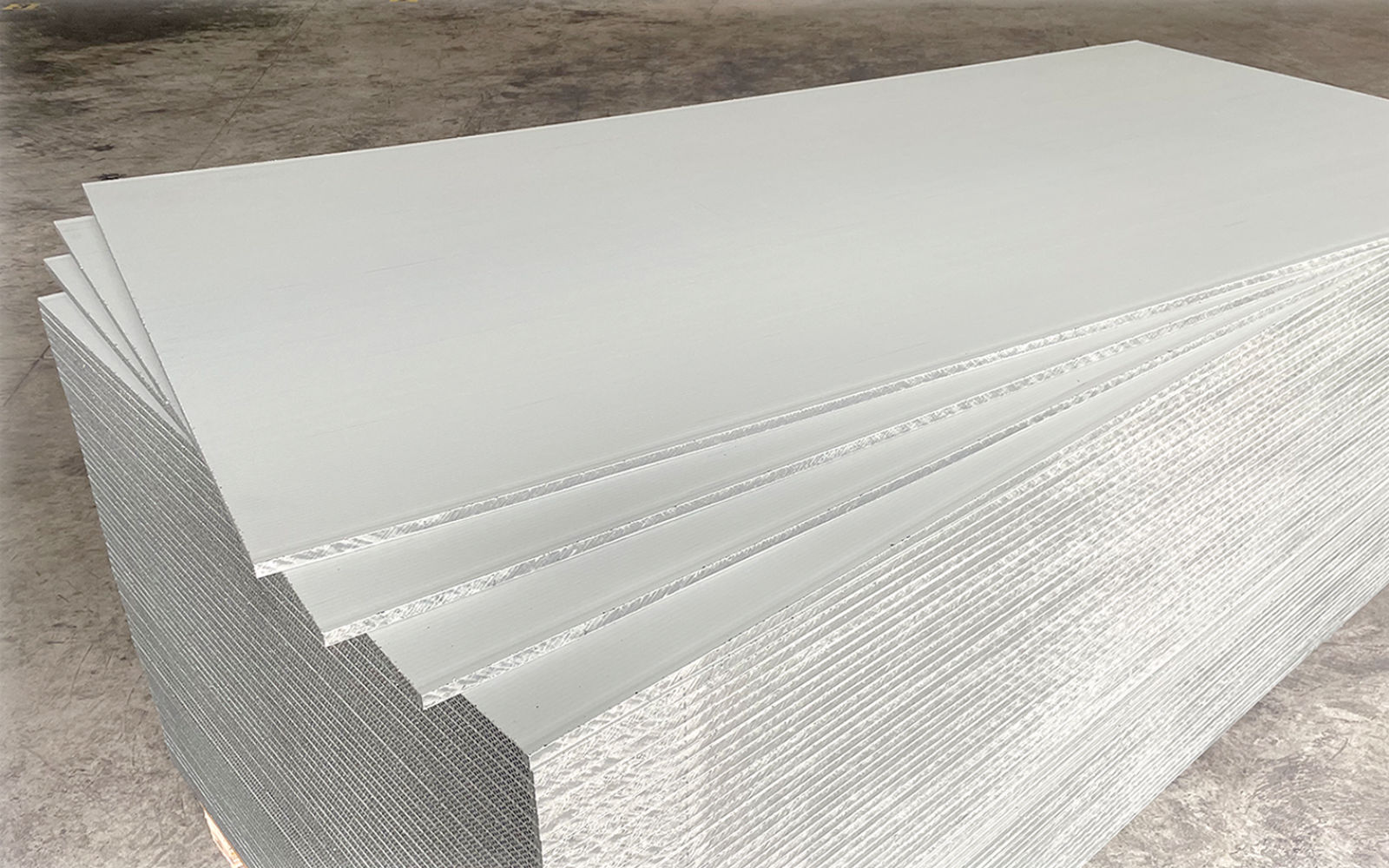

Ecoboard is a plastic hollow board primarily used as a formwork material for concrete casting. It is composed of polypropylene plastic which gives its high durability, smooth surface, high heat and water resistance properties. As an alternative to traditional wooden formworks, i.e. phenolic boards, Ecoboard saves both on construction cost, through its reusability; and time, through its workability. While this lightweight board can be used multiple times, increasing work productivity, it also has a wide array of applications such as lightweight partitions, modular cabinets and shelves.

FEATURES

COST EFFICIENT & REUSABLE

Can be reused over 30x without difficulty.* Cost is effectively lower compared to traditional wooden formworks.

EASY TO USE & TRANSPORT

Formwork installation and removal is faster given the workability and lightweight properties of the plastic board, can be easily cut, nailed, screwed and drilled.

WATERPROOF

High water resistance. No water absorption or bubbling even if left under wet conditions.

SURFACE ABRASION RESISTANT

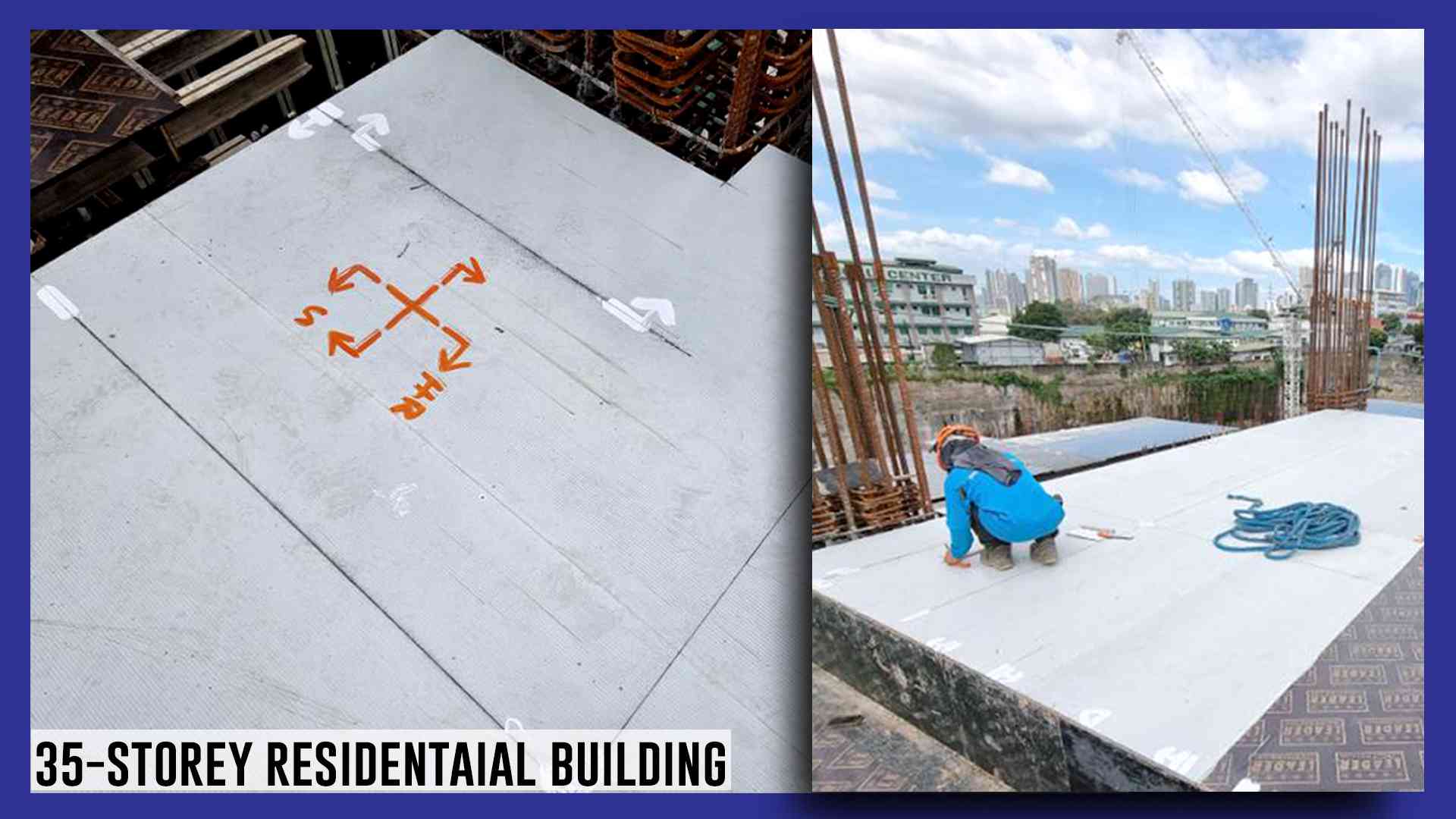

Surface is smooth and can withstand abrasion especially during stripping / dismantling after concrete is dried, thereby allowing a smoother concrete finish.

HEAT / CHEMICAL RESISTANT

Suitable under a wide range of weather conditions (-10 to 90 deg C). Surface is resistant to chemicals and other substances that would otherwise damage traditional formworks.

MINIMAL MAINTENANCE

Can be stored over a long period of time without preventive maintenance. Surface is easily cleaned by washing in order for multiple use.

* Subject to on-site handling, proper usage, and maintenance

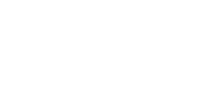

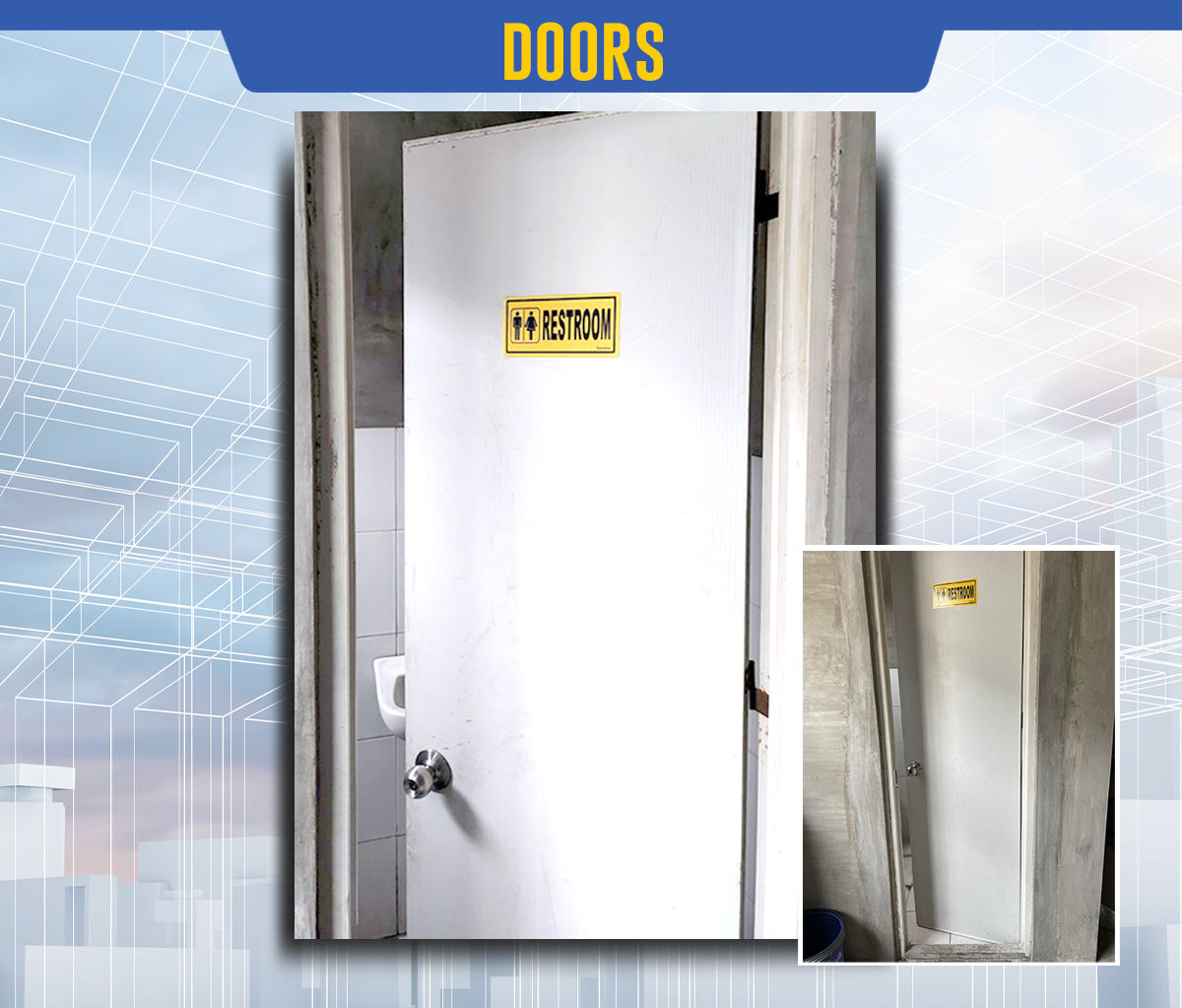

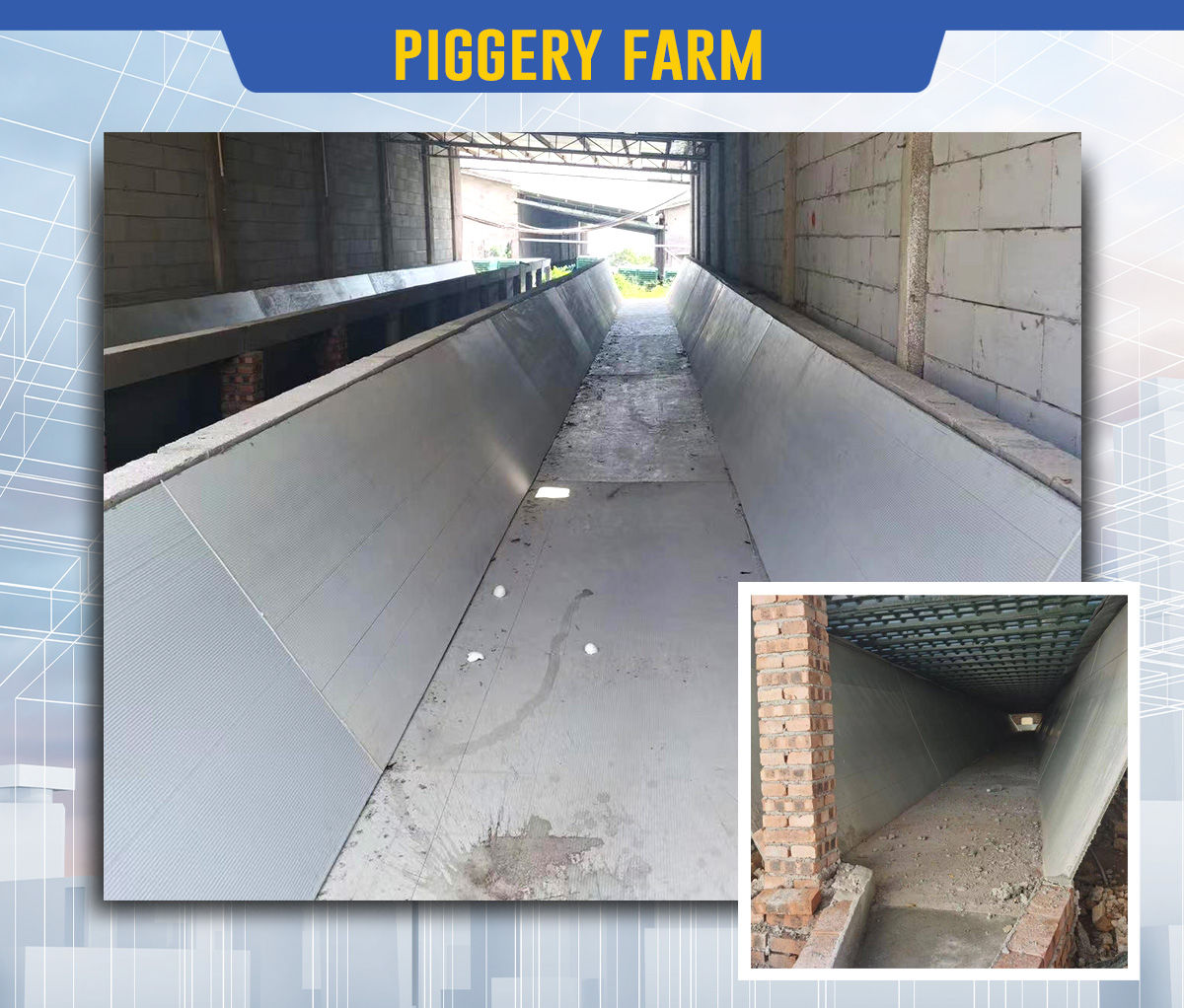

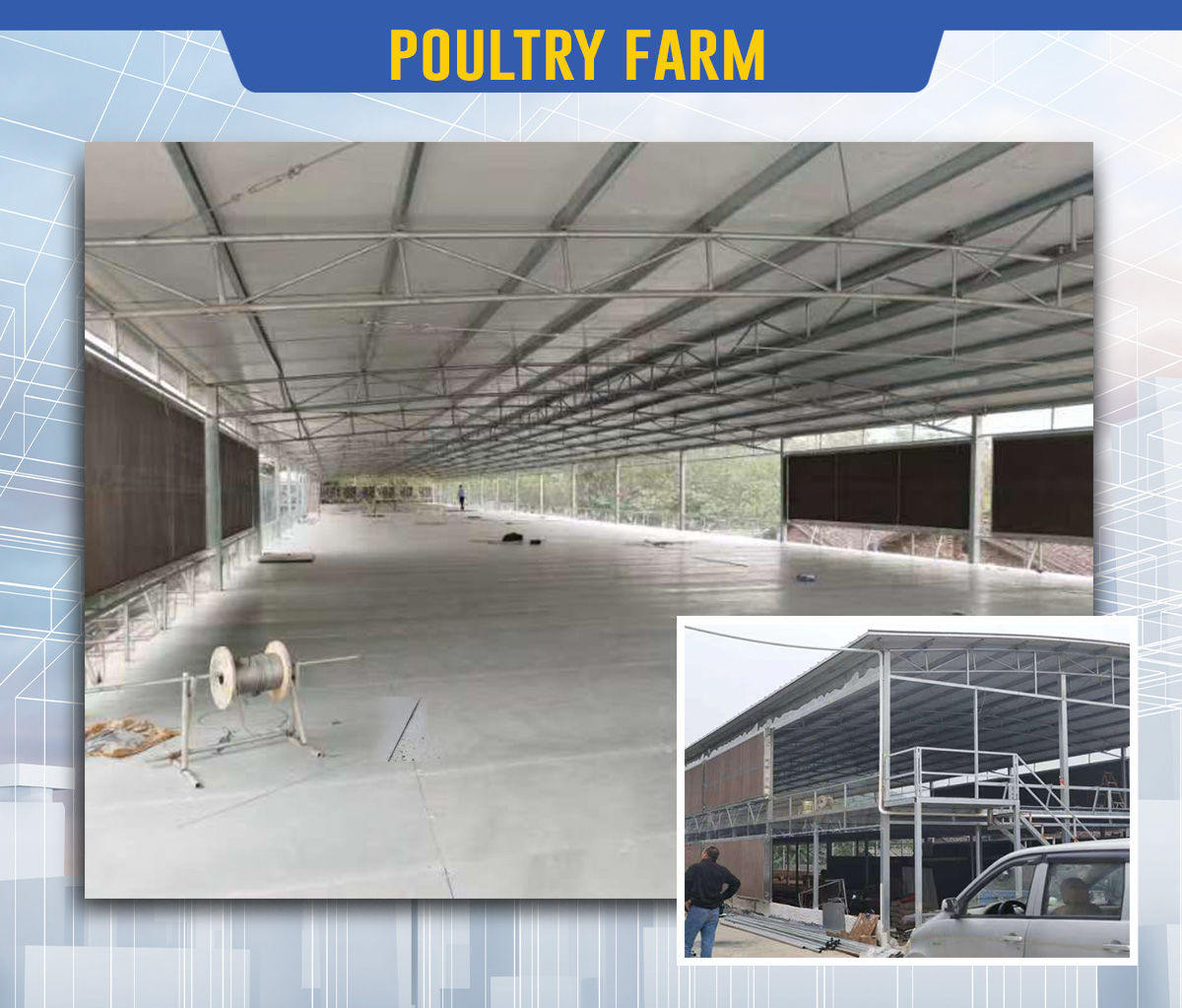

OUR PROJECTS

COST SAVINGS

18 MM OR 3/4 INCH

* Prices may be subject to change

** Subject to on-site handling, proper usage, and maintenance

BUDGET-FRIENDLY CLASS B PPR PLASTIC FORMWORKS

Recommended for smaller projects

DIMENSIONS

WIDTH X LENGTH:

1220MM x 2440MM (4 FT X 8 FT)

(In MM)

(Est Per Piece)

TECHNICAL SPECS

* Using sample size: 1830 MM x 915 MM x 15 MM

FORMWORK COMPARISON

* Subject to on-site handling, proper usage, and maintenance